Liquid nitrogen has got numerous industrial and medical applications. Liquid nitrogen plant working principle is based on cryogenic distillation of liquid air. Liquid nitrogen is nitrogen in a liquid state at an extremely low temperature. It is a colorless liquid having boiling point of (−195.79 °C). It is often abbreviated as LIN. However, LIN is a cryogenic fluid that can cause quick freezing on coming in contact with living tissue. Considering its cryogenic temperature, nitrogen needs to be shielded from the ambient heat. Cryogenic storage tanks are specially designed to store and transport. The tanks are designed with high quality materials to withstand extreme temperature and pressure. With liquid nitrogen storage the loss of nitrogen is reduced to 2% or less per day compared to gaseous storage.

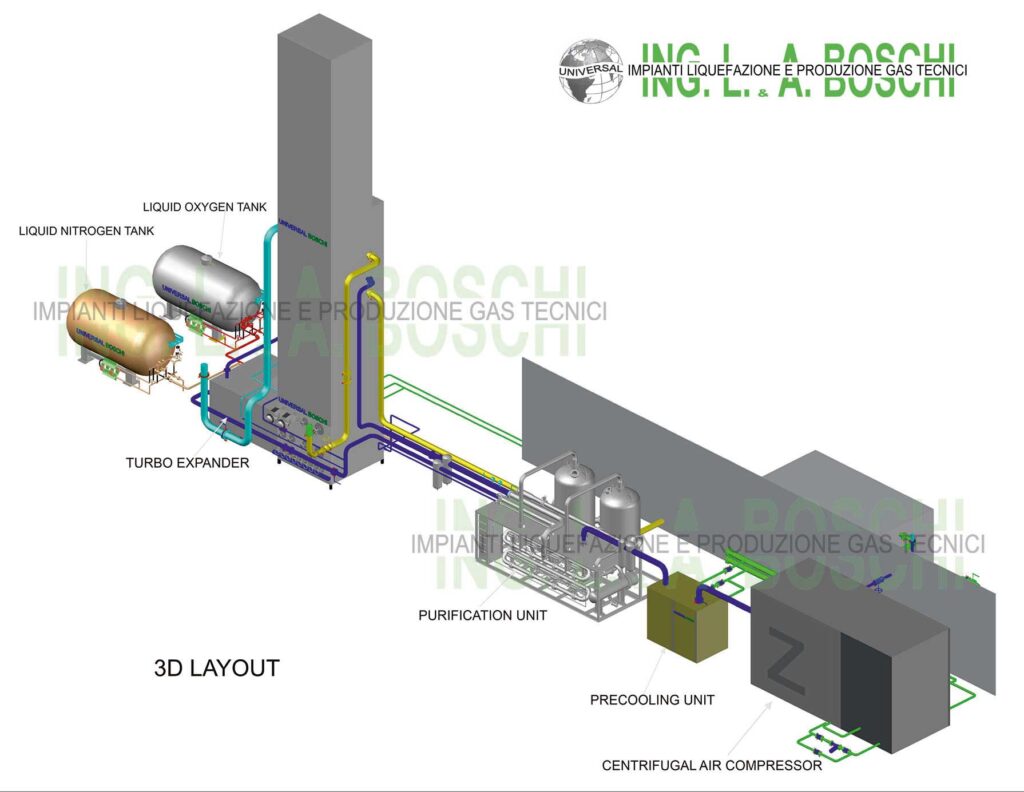

Liquid Nitrogen Production Process- Layout 3D Chart

Cryogenic distillation is the liquid nitrogen plant working principle based on cryogenic distillation of liquefied air. After the atmospheric air is let into the air separation unit it is compressed in the air compressor. After being compressed, the air is sent into the cleanup system where impurities such as moisture, hydrocarbons and carbon dioxide are removed. Then, the air is passed through heat exchangers where it is cooled to cryogenic temperatures. At this point, nitrogen is directed into the high pressure distillation column where nitrogen is physically separated from other gases and is formed at the top of the column. Nitrogen is removed from the column and is moved to low pressure column where it is distilled till it meets the commercial specifications for purity.

Our liquid nitrogen plant working principle is driven by cryogenic distillation. This technology is considered efficient, low cost and is instrumental in generating high purity nitrogen. LIN is easily transported source of dry nitrogen gas. Moreover, liquid nitrogen can maintain temperatures that are considerably below the freezing point of water making it useful in wide range of applications such as open-cycle refrigerant.

Applications of Liquid Nitrogen

- Used for removing unsightly or potentially malignant skin lesions such as warts and actinic keratosis

- Storing cells at low temperature for laboratory work

- Backup for nitrogen source in hypoxic air fire prevention systems

- Used for immersion, freezing, and transportation of food products

- Preservation of blood, reproductive cells (sperm and egg), and other biological samples and materials

- Cryo-conservation of animal genetic resources

- Shrink-weld machinery parts together

Liquid nitrogen is dangerous to handle because of its extremely low temperature. It is recommended that special care should be taken while handling LIN. Special gloves are used for handling the liquid so that there is no untoward incident. Customers all over the globe trust liquid nitrogen plant working principle based on fractional distillation for generation of high purity nitrogen.