First of all you should know about production process of nitrogen gas plant with cryogenic technology before going ahead and buying the plant machinery. Compared with non-cryogenic processes (PSA, VPSA), cryogenic distillation technology is more efficient and generates higher purity nitrogen. It is used on big scale in preservation of food, biological specimens (semen, blood), removal of skin warts, etc. With the cryogenic plant, you can increase the productivity of your business and is cost effective. The gas plant functions with pressure in the range 2-5 bar and generated nitrogen with purity up to 99.99%. On installing our machinery, you will recover the cryogenic plant cost within two years.

Cryogenic nitrogen plant is an industrial system that produces nitrogen by liquefaction of atmospheric air in the air separation unit (ASU). Nitrogen is one of the most important industrial gases comprising around 78% of earth’s atmosphere by mass. In fact, it is known as the largest industrial gas because of its extensive industrial applications. This gas is known for its inert properties because of which it finds applications in running manufacturing operations. It is used in manufacturing of electronic, brewing beer and food packaging. There are many other important applications of the inert gas. Industries meet their nitrogen requirements either through subscribing nitrogen cylinders or by installing onsite liquid nitrogen plant.

More and more industries and businesses are now opting to install cryogenic nitrogen gas plant because it is it is efficient, cost-effective and provides the inert gas available whenever you want. Subscribing nitrogen cylinders is fraught with lot of uncertainties because of supply chain issues. Moreover, using the inert gas through cylinders is expensive as well. Installing your liquid nitrogen plant will reduce the costs while ensuring constantly supply of the inert gas. Our plant machinery offers impressive return on investment (ROI). It is expected that the plant will break even within two years which is very impressive. There are numerous other benefits of producing your own nitrogen like you will be able to use all the nitrogen you have produced unlike cylinders where around 10% nitrogen remains unused.

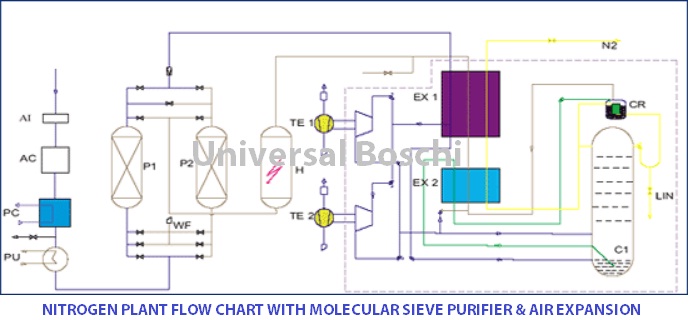

Nitrogen is produced in the cryogenic nitrogen plant by taking atmospheric air. When the atmospheric air is taken inside the air separation unit (ASU), it is compressed in the compressor. Then, it is moved through the cleanup system where impurities like hydrocarbons, moisture and carbon dioxide are eliminated. Here, the air is directed into the heat exchangers to liquefy it at cryogenic temperatures. At this stage, the air is put through high pressure distillation column where nitrogen is physically separated from oxygen and other gases. Nitrogen so formed is collected and put into a low pressure distillation column where it is distilled till it meets commercial specifications.